I had the opportunity to visit Springfield, Missouri this past week with the intent of visiting all 3 White River Marine boat plants including Ranger, Triton, and Nitro Boats.

The Collins Boating Pro Team made the cross-country trip with hopes of gaining product knowledge and a better understanding of just how these boats are manufactured.

I love bass boats and I have always tried to stay well-informed on the different models offered by each brand and the features of each. But after visiting each of these plants, I have a newfound respect for the process by which these boats are built. The level of work and pure craftsmanship that goes into each of these boats can’t be imagined unless you see it for yourself. Luckily I was able to do so!

Ranger Boats – Flippin Arkansas

My trip started at Ranger Boats in Flippin, Arkansas. The Ranger name is synonymous with bass fishing. When I hear the word “Ranger” I immediately think of their legacy and their history in the world of bass fishing. This was the plant I was most excited to visit as I will be running a Ranger Z520R in 2023.

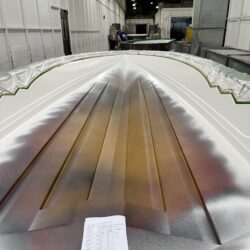

Of the 3 facilities I visited, Ranger Boats has the biggest plant. It employs 800 people and produces 15 boats per day. Ranger has fine-tuned their production process and puts a lot of work into just 1 single boat. The first thing that struck me was the amount of foam Ranger uses. They literally fill every void in the hull with foam to help with flotation. I’ve always heard Rangers don’t sink and now I see why.

One of the coolest things I saw in the factory was when they combined the top cap of the boat with the hull and created one solid piece of construction. They used a hoist to drop the top cap down onto the hull and using some type of permanent sealant/glue the 2 pieces are combined forever. I posted a video of this on my Facebook page.

Taking a factory tour ultimately helps an angler appreciate what he is standing on during a day on the water. You understand what goes into the boat, how it’s built, how it’s laid out, and how many people actually touch that boat before it ends up in your possession. I have a newfound respect for the boat-building process after visiting Ranger.

Triton Boats – Midway, Arkansas

On the second leg of the trip, I visited the Triton Boats plant in Midway, Arkansas. The Triton plant was about one-third of the size of the Ranger plant. Which in my opinion gave the operation a more “homey” feel. Because the plant was smaller it felt more like everyone knew everyone and had a bit more of a family atmosphere.

A ton of hard work and sweat is put into each of the boats at Triton. It also seemed a more manual process at that plant as there wasn’t as much equipment at Triton when compared to Ranger. As seen in one of the images below, it truly does take a team of employees to create just one boat.

I was informed by our guide, that Triton is now operated by a pair of new managers that have high hopes for the boat company and have big plans for Triton the near future. I’m looking forward to seeing what Triton has in store for anglers in 2023 and beyond.

Nitro Boats – Clinton, Missouri

I visited Nitro last on my tour but truthfully may have been the most impressed with their facility. The Nitro boat plant seemed to be very organized, clean, and well-maintained. The people there were extremely nice and literally seemed to enjoy what they were doing. I was most impressed with the Nitro Boats plant manager who has been working with the company for over 30 years. He was incredibly knowledgeable about his product and the process by which it’s built.

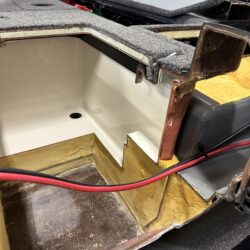

The Nitro team has many quality control measures in place to ensure the final product is as pristine as possible. Each boat is water tested in an indoor tank they have in the facility. One thing I noted about the Nitro is they do use wood in their boats. They use a combination of either marine-grade plywood or balsa to help create additional strength in their boats. Nitro seemed a little more secretive than the other brands as my team and I couldn’t take pictures of their process without their approval. And they didn’t approve many pictures 🙂 I actually respected their “limited picture” policy and the idea they wanted to keep some trade processes secret.

When asked what the most popular boat model moving through their plant was, the plant manager replied the Z19 and Z20 were the most popular.

Final Impressions

I was thoroughly impressed by each of these boat brands. I don’t think anglers can go wrong with either brand. All 3 of these boat companies have stringent quality control measures in place and have employed individuals who are pure craftsmen and love to build boats. Anglers can’t go wrong with any of the White River Marine brands.

Public tours are available and I highly recommend all potential boat owners to take a trip and visit these plants. You will gain a better understanding of how your boat is built and will better respect the countless hours poured into each model.